ý luận nhị nguyên trắng đen là điểm yếu cố hữu trong cách suy nghĩ của con người, đặc biệt nghiêm trọng với người Việt. Thế nên họ rất dễ mắc vào cách suy nghĩ máy móc, những logic hình thức, đặc biệt là cũng chính vì thế nên dễ bị lừa gạt, lợi dụng. Như thế nào là lý luận nhị nguyên, câu chuyện nảy sinh từ tranh luận của tôi với một người bạn về cúm mùa (ở đây không nhằm phê phán ai, vì ai cũng có thể mắc vào những lỗi như thế).

ý luận nhị nguyên trắng đen là điểm yếu cố hữu trong cách suy nghĩ của con người, đặc biệt nghiêm trọng với người Việt. Thế nên họ rất dễ mắc vào cách suy nghĩ máy móc, những logic hình thức, đặc biệt là cũng chính vì thế nên dễ bị lừa gạt, lợi dụng. Như thế nào là lý luận nhị nguyên, câu chuyện nảy sinh từ tranh luận của tôi với một người bạn về cúm mùa (ở đây không nhằm phê phán ai, vì ai cũng có thể mắc vào những lỗi như thế).

Ví dụ 1: gọi là cúm mùa là vì nó trở nặng trong mùa đông, giảm đi trong mùa hè! Nên một số người lý luận loanh quanh một lúc, câu chuyện nó trở thành: cúm mùa chỉ có trong mùa đông, không có trong mùa hè, vậy nguồn cúm mùa ở đâu ra, chính là “trời giáng ôn dịch” xuống loài người rồi! Chuyện này rất đơn giản, thực ra cúm mùa lây quanh năm, kể cả mùa hè, khác chăng là ở các nước ôn đới, cúm mùa trở nên mạnh hơn vào mùa đông hơn, thế thôi!

Ví dụ 2: nghệ sĩ nuôi khán giả hay khán giả nuôi nghệ sĩ!? Mọi hoạt động kinh tế nó đều là “xoay vòng”, nếu tự cung, tự cấp, tự sản xuất, tự tiêu thụ thì… đâu có gọi là kinh tế! Chính vì bản chất của mọi hoạt động kinh tế đều là “quần vòng” như thế, nên dùng cái chữ “kinh tế quần vòng”, nó gần như là vô nghĩa! Vậy thì ai nuôi ai? Cách đặt vấn đề như thế là đám lưu manh lợi dụng điểm yếu tư duy để kích động dư luận, kích động ghen ghét vụn vặt!

Ví dụ 3: phim ảnh tạo ra tội phạm, hay phim ảnh chỉ phản ánh thực tế nhiều tội phạm!? Hỏi điều này nó cũng giống như hỏi: tại sao giọt nước biển có vị mặn, đâu phải chỉ có một giọt nước mặn đâu, cả cái biển nó mặn đấy chứ! Thực tế hay phim ảnh, đều là những tấm gương phản chiếu lẫn nhau, phản chiếu qua lại “vô hạn” lần, thực tế nào thì phim ảnh đó và ngược lại, thế thôi, ở đây, đâu là “gà”, đâu là “trứng”, đâu là “nhân”, đâu là “quả”?

Chỉ cần mở một trang báo hàng ngày ra, đọc vài cái tựa là phát hiện ra vô số kiểu logic trắng đen nhị nguyên này! Thực tế mọi vận động trong cuộc sống luôn có chiều thời gian, cố tình bỏ quên cái chiều này là biến thành những khái niệm “trắng / đen” chết, xa rời thực tế! Chính vì cái “lỗi tư duy” này của người Việt mà họ rất dễ bị lợi dụng, luôn bị đẩy vào các tranh luận nhảm nhí, bị kích động bởi những thứ như “con gà hay quả trứng có trước”.

Đám lưu manh thì lợi dụng triệt để điều này, bỏ cái chiều thời gian đi, đảo ngược trình tự, biến thành một sự việc khác hẳn! Thêm một ví dụ khác gần đây trên báo là “zero-covid hay là sống-chung-với-dịch”, vì nó đã thành cái bệnh tư duy cố hữu rồi, nên vẫn cứ phải vin vào đó! Làm sao để sửa bệnh tư duy nhị nguyên trắng đen? Theo tôi bước đầu tiên là… chơi thể thao nhiều, tập thể dục thật nhiều, cảm nhận dòng chảy của thời gian, của vận động! 😃

uffalo như cái tên của nó (con trâu), là con tàu vận tải 540 tấn của Hải quân Hoàng gia, đóng ở Ấn Độ bằng gỗ giá tỵ. Buffalo đi đi về về giữa Anh và Úc, chở phạm nhân, hàng hoá. Năm 1824, đại dịch tả toàn cầu lan ra khắp châu Á. Nhưng tới năm 1832, làn sóng dịch thứ 2 mới lan tới Anh. Trên phạm vi toàn cầu, cả chục triệu người đã chết!

uffalo như cái tên của nó (con trâu), là con tàu vận tải 540 tấn của Hải quân Hoàng gia, đóng ở Ấn Độ bằng gỗ giá tỵ. Buffalo đi đi về về giữa Anh và Úc, chở phạm nhân, hàng hoá. Năm 1824, đại dịch tả toàn cầu lan ra khắp châu Á. Nhưng tới năm 1832, làn sóng dịch thứ 2 mới lan tới Anh. Trên phạm vi toàn cầu, cả chục triệu người đã chết!

aptain là con tàu mang số phận bi thảm, tàu lật và chìm ngay trong chuyến thử nghiệm đầu tiên, 500 sinh mạng bị lãng phí! Câu chuyện lần nữa cho thấy, ý kiến của đám đông ngu dốt chỉ mang lại thảm hoạ mà thôi! Chuyện bắt đầu với tháp pháo xoay, thiết kế của thuyền trưởng Cowper Phipps Coles năm 1855, về cơ bản là đi trước thời đại, thay vì dùng dãy nhiều súng, con tàu được thiết kế chỉ có vài tháp pháo xoay, có thể bắn được nhiều hướng mà không phải quay thuyền. Ít súng hơn, tức là súng phải to hơn, và công nghệ chế tạo đã cho phép có những khẩu súng cỡ nòng 200 ~ 300 mm, nặng cả vài chục tấn!

aptain là con tàu mang số phận bi thảm, tàu lật và chìm ngay trong chuyến thử nghiệm đầu tiên, 500 sinh mạng bị lãng phí! Câu chuyện lần nữa cho thấy, ý kiến của đám đông ngu dốt chỉ mang lại thảm hoạ mà thôi! Chuyện bắt đầu với tháp pháo xoay, thiết kế của thuyền trưởng Cowper Phipps Coles năm 1855, về cơ bản là đi trước thời đại, thay vì dùng dãy nhiều súng, con tàu được thiết kế chỉ có vài tháp pháo xoay, có thể bắn được nhiều hướng mà không phải quay thuyền. Ít súng hơn, tức là súng phải to hơn, và công nghệ chế tạo đã cho phép có những khẩu súng cỡ nòng 200 ~ 300 mm, nặng cả vài chục tấn!

acebook nhắc ngày này 5 năm trước, the ship’s cat, HMS Hermione. 😀 Quay trở lại Thời đại thuyền buồm, The-age-of-Sail, trên những con tàu gỗ, mèo là 1 thành viên không thể thiếu của thuỷ thủ đoàn, tàu nào cũng có ít nhất 1 con, lý do đơn giản là để bắt chuột… Cái thời xa xưa ấy, khi tàu bè còn nhỏ bé và hay lắc lư, thuỷ thủ đoàn đều ngủ trên những chiếc võng (hammock), và mèo cũng như mọi thành viên khác, cũng có 1 cái võng của riêng mình…

acebook nhắc ngày này 5 năm trước, the ship’s cat, HMS Hermione. 😀 Quay trở lại Thời đại thuyền buồm, The-age-of-Sail, trên những con tàu gỗ, mèo là 1 thành viên không thể thiếu của thuỷ thủ đoàn, tàu nào cũng có ít nhất 1 con, lý do đơn giản là để bắt chuột… Cái thời xa xưa ấy, khi tàu bè còn nhỏ bé và hay lắc lư, thuỷ thủ đoàn đều ngủ trên những chiếc võng (hammock), và mèo cũng như mọi thành viên khác, cũng có 1 cái võng của riêng mình…

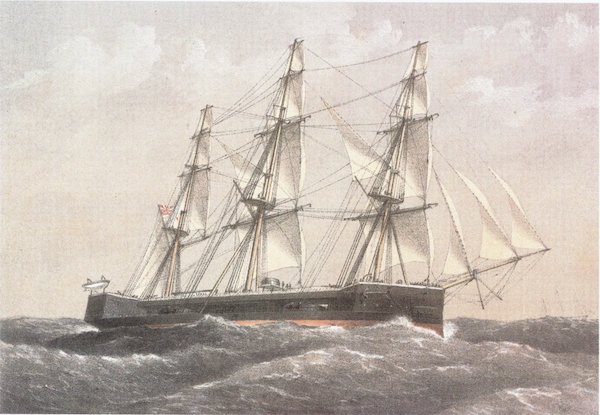

ửa cuối thế kỷ 19 bắt đầu kỷ nguyên bùng nổ về công nghệ: đóng tàu, động cơ, súng và đạn, etc… tất cả liên tục thay đổi, khiến cho một con tàu đóng xong chưa tới 10 năm đã thành lạc hậu! Warrior là con tàu như thế, hạ thuỷ năm 1861 để đối trọng lại với một con tàu Pháp – Gloire đi vào phục vụ một năm trước đó! Nhưng Warrior ở một đẳng cấp hoàn toàn khác, lúc hoàn thành, Warrior là tàu chiến lớn nhất, hiện đại nhất thế giới!

ửa cuối thế kỷ 19 bắt đầu kỷ nguyên bùng nổ về công nghệ: đóng tàu, động cơ, súng và đạn, etc… tất cả liên tục thay đổi, khiến cho một con tàu đóng xong chưa tới 10 năm đã thành lạc hậu! Warrior là con tàu như thế, hạ thuỷ năm 1861 để đối trọng lại với một con tàu Pháp – Gloire đi vào phục vụ một năm trước đó! Nhưng Warrior ở một đẳng cấp hoàn toàn khác, lúc hoàn thành, Warrior là tàu chiến lớn nhất, hiện đại nhất thế giới!

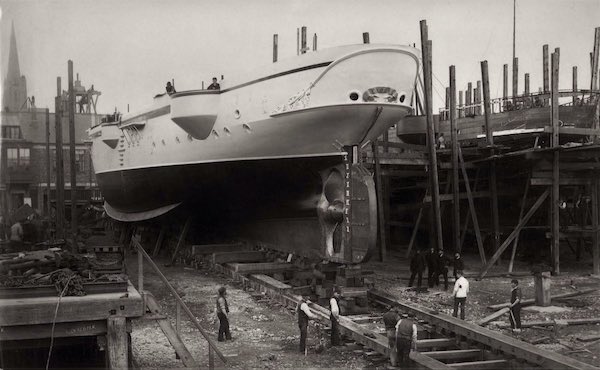

s Archimedes là con tàu hơi nước đầu tiên dùng chân vịt (propeller) thay vì guồng xoay (paddle-wheel). Bộ Hải quân nhận ra đây là cải tiến cần phải có trên tàu chiến, chân vịt nằm phía sau và sâu dưới nước, khả năng trúng đạn thấp hơn nhiều so với guồng xoay, đồng thời không chiếm không gian lớn giữa thân tàu làm cho khó bố trí súng. Họ bắt tay vào đóng con tàu Rattler, 1843 để thử nghiệm.

s Archimedes là con tàu hơi nước đầu tiên dùng chân vịt (propeller) thay vì guồng xoay (paddle-wheel). Bộ Hải quân nhận ra đây là cải tiến cần phải có trên tàu chiến, chân vịt nằm phía sau và sâu dưới nước, khả năng trúng đạn thấp hơn nhiều so với guồng xoay, đồng thời không chiếm không gian lớn giữa thân tàu làm cho khó bố trí súng. Họ bắt tay vào đóng con tàu Rattler, 1843 để thử nghiệm.

ặc dù tàu hơi nước đã xuất hiện từ những năm cuối thế kỷ 18, đầu tiên là những con tàu chạy trên sông, sau đó là những con tàu đi biển, nhưng máy móc hơi nước vẫn tiếp tục phát triển rất chậm, ứng dụng của máy hơi nước vào Hải quân thậm chí còn chậm hơn! Những máy hơi nước đầu tiên to lớn, nặng nề, thiếu ổn định, cộng thêm với lượng than lớn mang theo chiếm hầu hết tải trọng hữu ích của tàu! Với tàu chiến, điều đó có nghĩa là không còn mấy không gian và tải trọng để lắp đặt thêm súng!

ặc dù tàu hơi nước đã xuất hiện từ những năm cuối thế kỷ 18, đầu tiên là những con tàu chạy trên sông, sau đó là những con tàu đi biển, nhưng máy móc hơi nước vẫn tiếp tục phát triển rất chậm, ứng dụng của máy hơi nước vào Hải quân thậm chí còn chậm hơn! Những máy hơi nước đầu tiên to lớn, nặng nề, thiếu ổn định, cộng thêm với lượng than lớn mang theo chiếm hầu hết tải trọng hữu ích của tàu! Với tàu chiến, điều đó có nghĩa là không còn mấy không gian và tải trọng để lắp đặt thêm súng!

ý luận nhị nguyên trắng đen là điểm yếu cố hữu trong cách suy nghĩ của con người, đặc biệt nghiêm trọng với người Việt. Thế nên họ rất dễ mắc vào cách suy nghĩ máy móc, những logic hình thức, đặc biệt là cũng chính vì thế nên dễ bị lừa gạt, lợi dụng. Như thế nào là lý luận nhị nguyên, câu chuyện nảy sinh từ tranh luận của tôi với một người bạn về cúm mùa (ở đây không nhằm phê phán ai, vì ai cũng có thể mắc vào những lỗi như thế).

ý luận nhị nguyên trắng đen là điểm yếu cố hữu trong cách suy nghĩ của con người, đặc biệt nghiêm trọng với người Việt. Thế nên họ rất dễ mắc vào cách suy nghĩ máy móc, những logic hình thức, đặc biệt là cũng chính vì thế nên dễ bị lừa gạt, lợi dụng. Như thế nào là lý luận nhị nguyên, câu chuyện nảy sinh từ tranh luận của tôi với một người bạn về cúm mùa (ở đây không nhằm phê phán ai, vì ai cũng có thể mắc vào những lỗi như thế).