ó những điều không hẳn là KHKT, nó thuộc về common-sense. Hàng chục năm trước, kayak chế tạo sẵn thường dài 17, 18 feet, nhưng vài năm trở lại đây, đa số các mẫu có trên thị trường đã giảm chiều dài đáng kể, còn 14, 15 feet. Phải mất một thời gian khá lâu, người ta mới nhận ra, với một người bình thường, chèo chậm rãi 4 ~ 6 kmh, thì 17, 18 là quá dài, không phải ai cũng đủ thể lực và sức bền để lợi dụng được chiều dài đó, 14 ~ 15, mặc dù hy sinh tải trọng chút, nhưng chèo thoải mái hơn.

ó những điều không hẳn là KHKT, nó thuộc về common-sense. Hàng chục năm trước, kayak chế tạo sẵn thường dài 17, 18 feet, nhưng vài năm trở lại đây, đa số các mẫu có trên thị trường đã giảm chiều dài đáng kể, còn 14, 15 feet. Phải mất một thời gian khá lâu, người ta mới nhận ra, với một người bình thường, chèo chậm rãi 4 ~ 6 kmh, thì 17, 18 là quá dài, không phải ai cũng đủ thể lực và sức bền để lợi dụng được chiều dài đó, 14 ~ 15, mặc dù hy sinh tải trọng chút, nhưng chèo thoải mái hơn.

Haiza, nhớ lại những chiếc kayak khổng lồ ở vịnh Hạ Long, hình như là làm theo mẫu của Nga, toàn cho những tay đua Olympic có thể hình 90 ~ 110 kg… Suy nghĩ rất rất nhiều, có lẽ chiếc kế tiếp nên giảm chiều dài từ 17 feet xuống còn cỡ 16… Kể nghe chuyện ngoài lề, đám lưu manh vẫn rêu rao: thằng Xuyên đó ko chèo gì đâu, nó không chèo được nước ngược, nó cứ thả thuyền theo con nước đi một đoạn, xong đợi thuỷ triều đổi hướng rồi thả thuyền quay về nhà! Chuyện nghe được, thật 100% !!! 😃 😃

hé qua hội chợ triển lãm SECC vì nghĩ là có thứ mình cần, rinh ngay một cây “Japanese saw – cưa tay Nhật Bản – dozuki, lưỡi mỏng, răng cắt nằm xen kẽ và ngược so với các loại cưa khác, nên cho vết cắt mỏng, chậm nhưng chính xác, đặc biệt là với các loại gỗ trung bình & mềm. Dụng cụ có thể dùng cho ghe, xuồng, tàu buồm nhiều vô khối, nhìn mà ham…

hé qua hội chợ triển lãm SECC vì nghĩ là có thứ mình cần, rinh ngay một cây “Japanese saw – cưa tay Nhật Bản – dozuki, lưỡi mỏng, răng cắt nằm xen kẽ và ngược so với các loại cưa khác, nên cho vết cắt mỏng, chậm nhưng chính xác, đặc biệt là với các loại gỗ trung bình & mềm. Dụng cụ có thể dùng cho ghe, xuồng, tàu buồm nhiều vô khối, nhìn mà ham…

ôm đó đi mua mấy cây mây (rattan) dài gần 2m, đường kính khoảng 3 ~ 4 cm, và một mớ gỗ balsa về làm cái mái chèo kiểu Greenland, làm xong đem cân nặng đúng 0.8kg, tính hết cả sợi thuỷ tinh, keo, sơn… (!!!) xài tốt, nhẹ nhàng đến tận giờ! Bực mình cái là balsa là loại gỗ khá rẻ, nhưng vì phải nhập khẩu nên giá thành lại trở nên khá đắt! 😞 Nhân tiện giải thích về thuật ngữ “composite”… nhiều năm qua thấy có nhiều quan niệm rất “buồn cười” về composite, ai cũng nói kiểu “biết rồi” nhưng khi đụng tay vào việc thì lại thấy… nó không đúng như cái mình “biết”! Người thì bảo phải là epoxy và ván ép, người thì bảo là polyester và sợi thuỷ tinh, người thì bảo phải lót xơ dừa như kiểu làm vỏ lãi ở miền Tây, etc…

ôm đó đi mua mấy cây mây (rattan) dài gần 2m, đường kính khoảng 3 ~ 4 cm, và một mớ gỗ balsa về làm cái mái chèo kiểu Greenland, làm xong đem cân nặng đúng 0.8kg, tính hết cả sợi thuỷ tinh, keo, sơn… (!!!) xài tốt, nhẹ nhàng đến tận giờ! Bực mình cái là balsa là loại gỗ khá rẻ, nhưng vì phải nhập khẩu nên giá thành lại trở nên khá đắt! 😞 Nhân tiện giải thích về thuật ngữ “composite”… nhiều năm qua thấy có nhiều quan niệm rất “buồn cười” về composite, ai cũng nói kiểu “biết rồi” nhưng khi đụng tay vào việc thì lại thấy… nó không đúng như cái mình “biết”! Người thì bảo phải là epoxy và ván ép, người thì bảo là polyester và sợi thuỷ tinh, người thì bảo phải lót xơ dừa như kiểu làm vỏ lãi ở miền Tây, etc…

arious small updates for this Serene – 3 kayak still, I’ve could always found out somethings that could be improved. First, I’ve built a new paddle, a simple one with rattan shaft (sandwiched between 2 thin strips of wood) and slightly larger plywood blades. With lessons learnt from building previous paddles, this one is much stronger, and weights reasonably at exactly 1kg. I’ve also put some 3M reflective tapes on the paddles’ blades, which offer excellent reflection (see 2nd image below).

arious small updates for this Serene – 3 kayak still, I’ve could always found out somethings that could be improved. First, I’ve built a new paddle, a simple one with rattan shaft (sandwiched between 2 thin strips of wood) and slightly larger plywood blades. With lessons learnt from building previous paddles, this one is much stronger, and weights reasonably at exactly 1kg. I’ve also put some 3M reflective tapes on the paddles’ blades, which offer excellent reflection (see 2nd image below).

nother new paddle, almost done. It looks simple enough, but actually it’s not quite so. The paddle shaft is a composite of rattan and wood and is scaffed to an oval shape in cross-section (2.8 x 3.6 cm), which fits my hands perfectly. Rattan is very light and immensely flexible, but it tends to not keeping straight under constant load.

nother new paddle, almost done. It looks simple enough, but actually it’s not quite so. The paddle shaft is a composite of rattan and wood and is scaffed to an oval shape in cross-section (2.8 x 3.6 cm), which fits my hands perfectly. Rattan is very light and immensely flexible, but it tends to not keeping straight under constant load.

rước quen một số bạn Mỹ thuật Gia Định, chuyên ngành Sơn mài. Có thể nhiều người chưa biết, Sơn mài là một ngành mỹ thuật rất đặc thù của VN. Cứ sơn lên rồi lại mài đi, làm như thế 10, 15 lớp, thậm chí nhiều hơn. Làm tranh sơn mài tốn công hơn các loại tranh khác rất nhiều, nhưng bù lại, tranh có độ trong, độ sâu huyền ảo, do có nhiều lớp chất liệu chồng lên nhau. Nhắc nhớ vụ án gần đây, kiệt tác, bảo vật quốc gia đã “lên đường” do bị “phục chế” bằng… nước rửa chén. Cũng có ý kiến (có khả năng cao) cho rằng: có ai đó đã mượn việc “phục chế” này để tráo một bức tranh giả, tranh chép vào đấy, còn

rước quen một số bạn Mỹ thuật Gia Định, chuyên ngành Sơn mài. Có thể nhiều người chưa biết, Sơn mài là một ngành mỹ thuật rất đặc thù của VN. Cứ sơn lên rồi lại mài đi, làm như thế 10, 15 lớp, thậm chí nhiều hơn. Làm tranh sơn mài tốn công hơn các loại tranh khác rất nhiều, nhưng bù lại, tranh có độ trong, độ sâu huyền ảo, do có nhiều lớp chất liệu chồng lên nhau. Nhắc nhớ vụ án gần đây, kiệt tác, bảo vật quốc gia đã “lên đường” do bị “phục chế” bằng… nước rửa chén. Cũng có ý kiến (có khả năng cao) cho rằng: có ai đó đã mượn việc “phục chế” này để tráo một bức tranh giả, tranh chép vào đấy, còn

irst half of 2018 is kind of a huge mess for me, everything unsettled for quite a long period of time, and I could hardly find any times to go paddling at all 😢😢. You could guess what the feelings were like, when the newly – built kayak has to stay dried for an extended period of time, and the paddler dwell into a rather prolonged fatigue mood. However, things got better gradually, most of my works has come back on the right track, and it is just so wonderful to get back onto water again! 😀😀

irst half of 2018 is kind of a huge mess for me, everything unsettled for quite a long period of time, and I could hardly find any times to go paddling at all 😢😢. You could guess what the feelings were like, when the newly – built kayak has to stay dried for an extended period of time, and the paddler dwell into a rather prolonged fatigue mood. However, things got better gradually, most of my works has come back on the right track, and it is just so wonderful to get back onto water again! 😀😀

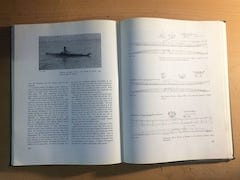

ón qùa của một người bạn già Mỹ gởi tặng… cuốn sách hard – copy, hard – cover:

ón qùa của một người bạn già Mỹ gởi tặng… cuốn sách hard – copy, hard – cover: