took great care in aligning a bilge’s parts, to make sure the final piece would come exactly to it designed shape, and to make sure the port and starboard bilges are identical, or else, the boat would have a twisted hull. All joints is slightly sanded, and applied a layer of glass on the internal side. Next come the job of putting everything together using a combination of fastening wires, super glue and duct tape. Having experiences from previous boat, I used very little steel wires this time.

took great care in aligning a bilge’s parts, to make sure the final piece would come exactly to it designed shape, and to make sure the port and starboard bilges are identical, or else, the boat would have a twisted hull. All joints is slightly sanded, and applied a layer of glass on the internal side. Next come the job of putting everything together using a combination of fastening wires, super glue and duct tape. Having experiences from previous boat, I used very little steel wires this time.

It’s so good to see the bilges fit naturally into their position, with minimum pressing, adjusting efforts. The tendency to take shape easily proves that you’ve all done right in the previous steps: measuring, drawing, cutting and jointing the biges. This is for the first time, you would have an initial impression, of how the boat would finally look like. The computer 3D renderings are too small to have a precise assessment, and of course, it’s always much more lively with a tangible object! 😀

Looking at these two halves: hull and deck, having a senses of every details, it’s easier to arrange and schedule the next tasks. There’re so many jobs ahead: make and install the (recessed) hatches, hatches’ locks, install the cockpit coaming, rudder pedals and control lines, compass, the bilge pump, etc… and of course the whole complex electric & electronic system. Things should be better done this time, with the lessons learnt (tediously and expensively) from previous boat projects.

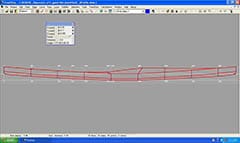

ext is jointing the plywood pieces: 8 joints for the hull, and just 1 for the deck, to form the bilges that would build up into the boat shape. For the 2 pairs of hull’s bilges, I flip one pair by 180 degree when drawing on the boards, so that to distribute the joints at different places across the boat length, and not to concentrate too much joints into one proximity. That old boatbuilding carpenter’s trick is not completely necessary with modern building techniques, but it’s nice to do so anyway.

ext is jointing the plywood pieces: 8 joints for the hull, and just 1 for the deck, to form the bilges that would build up into the boat shape. For the 2 pairs of hull’s bilges, I flip one pair by 180 degree when drawing on the boards, so that to distribute the joints at different places across the boat length, and not to concentrate too much joints into one proximity. That old boatbuilding carpenter’s trick is not completely necessary with modern building techniques, but it’s nice to do so anyway.

he progress is really slow lately, several weeks passed, but little get done 😢! Things started moving anyhow, I “quickly” transfer the “offset tables” onto the plywood boards, draw all the bilges, bulkheads, and other parts. The greatest thing of all is that now I’ve purchased very good sheets of plywood, not truly marine – grade (there’s no such in Vietnam), but high – grade water – resistance ones. I could feel it when do the sawing, the boards are quit tough, not fragile as with my previous ply!

he progress is really slow lately, several weeks passed, but little get done 😢! Things started moving anyhow, I “quickly” transfer the “offset tables” onto the plywood boards, draw all the bilges, bulkheads, and other parts. The greatest thing of all is that now I’ve purchased very good sheets of plywood, not truly marine – grade (there’s no such in Vietnam), but high – grade water – resistance ones. I could feel it when do the sawing, the boards are quit tough, not fragile as with my previous ply!

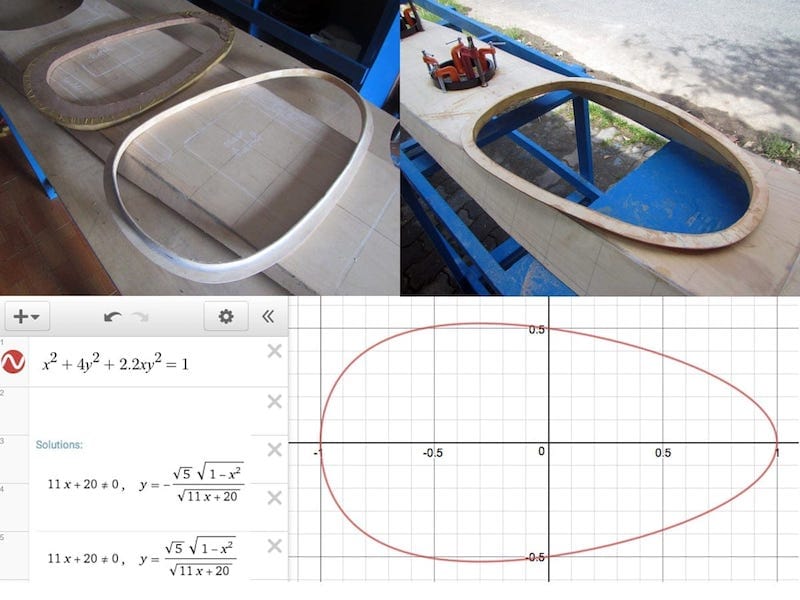

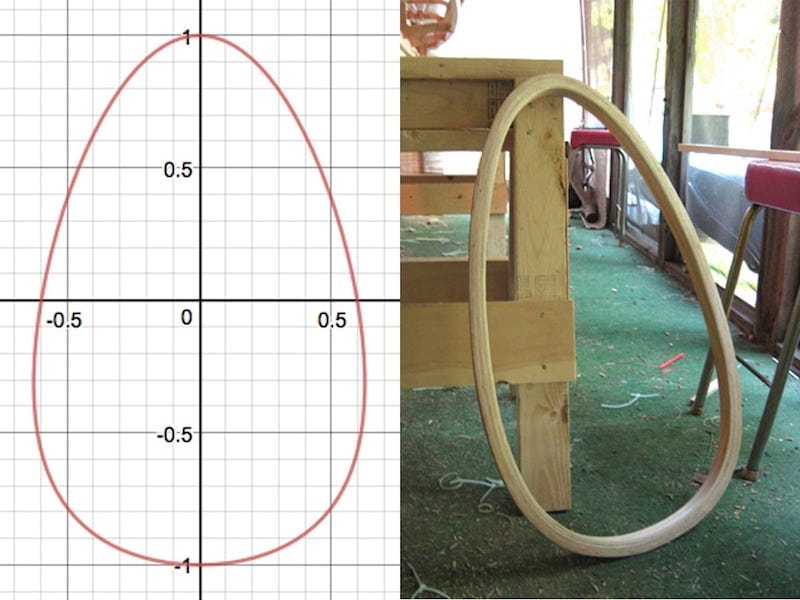

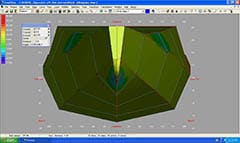

ver the years of designing and building wooden kayak, often a recurring question comes to my mind: how can we precisely construct a kayak cockpit shape in a mathematical way. Today, I spent 30 minutes to figure out the problem, it turned out to be quite easy indeed. But first of all, there are so many different shapes for cockpits, and everyone may have his / her own preference on how it should look like. Here I try to plot a shape that is most suited to my eyes, and closed to what’s usually called “an ocean cockpit” found on Greenland kayaks.

ver the years of designing and building wooden kayak, often a recurring question comes to my mind: how can we precisely construct a kayak cockpit shape in a mathematical way. Today, I spent 30 minutes to figure out the problem, it turned out to be quite easy indeed. But first of all, there are so many different shapes for cockpits, and everyone may have his / her own preference on how it should look like. Here I try to plot a shape that is most suited to my eyes, and closed to what’s usually called “an ocean cockpit” found on Greenland kayaks.

inally, I managed to have some time slots to start the kayak building. Works would be carried out mostly at weekends, and hopefully, the boat could be finished within this year. After much hesitations, procrastinations, and considerations into the very details, I’ve incorporated quite some “innovations” into the final design, as well as some “simplifications” to ease the building process. I “hope” this is also my “last” stitch – and – glue boat, the 6th of “the fleet”, seems to be a lot already! 😀

inally, I managed to have some time slots to start the kayak building. Works would be carried out mostly at weekends, and hopefully, the boat could be finished within this year. After much hesitations, procrastinations, and considerations into the very details, I’ve incorporated quite some “innovations” into the final design, as well as some “simplifications” to ease the building process. I “hope” this is also my “last” stitch – and – glue boat, the 6th of “the fleet”, seems to be a lot already! 😀

lso, the deck height right after the cockpit is reduced, so that climbing in the kayak would be easier. The hull’s upper bilges now have much more flare, especially at the 2 ends, to help improving secondary stability, that also has Cp (prismatic coefficient) increased to about 0.52 ~ 0.53, a value usually seen on a faster cruising kayak, unlike the quite – low value of 0.5 on my previous Serene – 2. Transverse metacentric height – Kmt increased to 26 ~ 27 cm, which indicates satisfactory initial stability.

lso, the deck height right after the cockpit is reduced, so that climbing in the kayak would be easier. The hull’s upper bilges now have much more flare, especially at the 2 ends, to help improving secondary stability, that also has Cp (prismatic coefficient) increased to about 0.52 ~ 0.53, a value usually seen on a faster cruising kayak, unlike the quite – low value of 0.5 on my previous Serene – 2. Transverse metacentric height – Kmt increased to 26 ~ 27 cm, which indicates satisfactory initial stability.

ẫn đang loay hoay suy nghĩ về thiết kế kayak, hard-chine hay là soft-chine, những đường cong mềm mại, hay những cạnh vát sắc nét, mỗi cái đều có ưu, nhược riêng. Dù anh có đi theo hướng nào, thì vẫn luôn có người làm ngược lại, đó đơn giản là sự đa dạng của suy nghĩ con người. Trong một thế giới lành mạnh, sự khác biệt đúng ra là để hỗ trợ, bổ sung cho nhau, thay vì kình chống nhau…

ẫn đang loay hoay suy nghĩ về thiết kế kayak, hard-chine hay là soft-chine, những đường cong mềm mại, hay những cạnh vát sắc nét, mỗi cái đều có ưu, nhược riêng. Dù anh có đi theo hướng nào, thì vẫn luôn có người làm ngược lại, đó đơn giản là sự đa dạng của suy nghĩ con người. Trong một thế giới lành mạnh, sự khác biệt đúng ra là để hỗ trợ, bổ sung cho nhau, thay vì kình chống nhau…