onitnue working on the deck part and the cockpit. But first… some pictures to show off the boat shapes, still quite a long way to the final forms, but look fascinating enough to me already, to quote a popular architectural saying:

onitnue working on the deck part and the cockpit. But first… some pictures to show off the boat shapes, still quite a long way to the final forms, but look fascinating enough to me already, to quote a popular architectural saying: form, IT IS function

😀! 3rd image below: the cockpit coaming being reinforced with some putty in the corner, then a layer of fiberglass tape the under side. 5th image: cockpit being jointed to the deck. There’re some miscellaneous jobs to be done on the hull still.

15 anchor points to be built into the hull. First, I glued small wood blocks alongside the gunwales, then drilled two holes (1 inch apart) into each block. Plastic lines 5 mm in diameter (the one usually used in fishery net) are run through, then putty is filled in, this way, just a small amount of putty is used. When the epoxy has cured, pull the lines out, you would have some “tunnels” to run the lashing through. Finally, small pieces of glass would cover and strengthen the wood blocks.

The cockpit coaming is glued, then glassed with the deck, two layers of fiberglass (one under and one upper), it’s very strong now, can withstand the weight of my whole body (while climbing onto it). For such a narrow kayak and small cockpit (45 cm in width, less internally), I don’t install any foot brace or thigh brace, and even back rest, the cockpit almost fits my lower body. I have no idea for a seat for now, maybe that I would just sit on the bare bottom, or with a thin layer of mattress.

Serene – 1 p1

Serene – 1 p2

Serene – 1 p3

Serene – 1 p4

[13 ~ 18] kg is the usual weight range of wooden kayaks, with the lighter being used for tourings, and the heavier as “expedition boats”. Plastic or FRP (fiberglass – reinforced plastic) boats are much heavier, often in the [25 ~ 30] kg range. In order to go below 12 kg…

…you would need a SOF (Skin on Frame) design, or make use of the expensive carbon, kevlar fibers (usually found in racing boats). So wood is a very ideal choice for kayaks (as well as any small watercraft), and I would be very happy to have mine aimed at the 17 ~ 18 kg target.

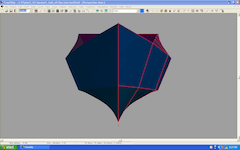

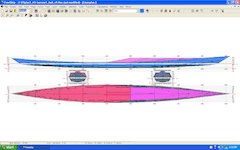

ost major tasks on the hull has been completed, now continue on the deck part. First is cutting out the fore and aft hatches’ holes and fit some reinforcement rims (the plywood is weak, it can deform badly around the hatches in the long run). The Beckson hatches are quite small indeed, the largest are 8″ in internal diameter, have to live with that for now anyhow since Beckson does not have a larger size. I also made a rough fairing on the external side of the deck. Next comes the cockpit.

ost major tasks on the hull has been completed, now continue on the deck part. First is cutting out the fore and aft hatches’ holes and fit some reinforcement rims (the plywood is weak, it can deform badly around the hatches in the long run). The Beckson hatches are quite small indeed, the largest are 8″ in internal diameter, have to live with that for now anyhow since Beckson does not have a larger size. I also made a rough fairing on the external side of the deck. Next comes the cockpit.

oat building is a labour – intensive process, and only skills and experiences could help to reduce workload and improve quality. Up until now, I’m quite pleased with the building, my 4th one. Today, I cut a slot into the aft hull to install the skeg box, the excellent Fein multimaster oscillating tool offers a nice cut as usual. Things went on smoothly, I have great confidence in this 5 cm fiberglass tape, it produces very fine and strong seam lines, so I decided to use just 2 layers (one inside, one outside).

oat building is a labour – intensive process, and only skills and experiences could help to reduce workload and improve quality. Up until now, I’m quite pleased with the building, my 4th one. Today, I cut a slot into the aft hull to install the skeg box, the excellent Fein multimaster oscillating tool offers a nice cut as usual. Things went on smoothly, I have great confidence in this 5 cm fiberglass tape, it produces very fine and strong seam lines, so I decided to use just 2 layers (one inside, one outside).

arious miscellaneous jobs in preparing for the next steps. First is glueing the skeg box and glassing the skeg blade (I use the “skeg in a well” as in my last boat, the skeg box is like a “well”, going through hull and through deck, a design that greatly facilitates maintenance and repair). Then forming the cockpit coaming by 2 nested narrow strips of 4 mm plywood, bending around the MDF frame cut earlier, the ply is so fragile that I had to brush it with a layer of epoxy to prevent cracks when bending.

arious miscellaneous jobs in preparing for the next steps. First is glueing the skeg box and glassing the skeg blade (I use the “skeg in a well” as in my last boat, the skeg box is like a “well”, going through hull and through deck, a design that greatly facilitates maintenance and repair). Then forming the cockpit coaming by 2 nested narrow strips of 4 mm plywood, bending around the MDF frame cut earlier, the ply is so fragile that I had to brush it with a layer of epoxy to prevent cracks when bending.

poxy resin and putty are the most crucial parts in small watercraft building, yet they’re the most annoying, paranoidly sticky and easy to mess around. It takes me a long time to learn how to use them properly. After filling all the internal seams with

poxy resin and putty are the most crucial parts in small watercraft building, yet they’re the most annoying, paranoidly sticky and easy to mess around. It takes me a long time to learn how to use them properly. After filling all the internal seams with

he bigles jointed very well, with just some neglectable tiny defects, port and starboard pairs match perfectly. Before putting them all together to form the initial boat shape, I applied a layer of penetrating epoxy (epoxy thinned with xylene), taking care so that the amount of epoxy used won’t exceed 0.6 kg overall. For this job, I use a kind of elastic epoxy with the

he bigles jointed very well, with just some neglectable tiny defects, port and starboard pairs match perfectly. Before putting them all together to form the initial boat shape, I applied a layer of penetrating epoxy (epoxy thinned with xylene), taking care so that the amount of epoxy used won’t exceed 0.6 kg overall. For this job, I use a kind of elastic epoxy with the

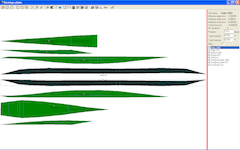

sing staples to clamp 2 sheets of plywood together, I then cut the hull’s planks, port and starboard, all is composed from 3 pieces. Then the deck’s pieces, and other parts: forward and aft bulkheads, skeg box and skeg blade… After 3 boats, I can now cut the wood with quite some accuracy. Sometimes, I’d wished to have the accuracy of a CNC machine, but such a machine that can cut in the 1.22 x 2.44 m dimension is not a possible option for most home builders, including me.

sing staples to clamp 2 sheets of plywood together, I then cut the hull’s planks, port and starboard, all is composed from 3 pieces. Then the deck’s pieces, and other parts: forward and aft bulkheads, skeg box and skeg blade… After 3 boats, I can now cut the wood with quite some accuracy. Sometimes, I’d wished to have the accuracy of a CNC machine, but such a machine that can cut in the 1.22 x 2.44 m dimension is not a possible option for most home builders, including me.

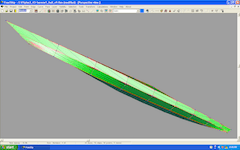

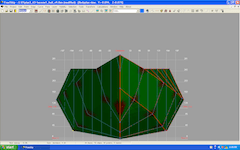

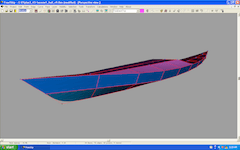

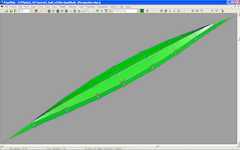

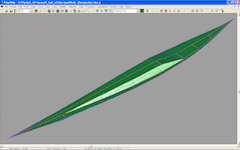

erene – 1 is quite a distinctive boat, originally took inspiration from the Black Pearl and the Anas Acuta, but in it current status, it shares not a single common point with them. The hull has been transformed into a light cruising one with long water line, deeper V bottom, little rockers and a very narrow beam (45 cm). There’re times that I’m worrying on the feasibility of the design, except for some theoretical calculations, there’s nothing to ensure me that it would be a good watercraft.

erene – 1 is quite a distinctive boat, originally took inspiration from the Black Pearl and the Anas Acuta, but in it current status, it shares not a single common point with them. The hull has been transformed into a light cruising one with long water line, deeper V bottom, little rockers and a very narrow beam (45 cm). There’re times that I’m worrying on the feasibility of the design, except for some theoretical calculations, there’s nothing to ensure me that it would be a good watercraft.

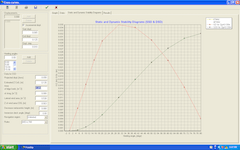

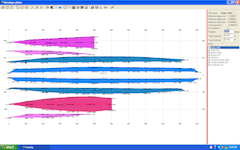

inalized my new kayak design, a considerable amount of work on optimizing the hull shape, adjusting it back and forth to find out the minimum drag numbers (based on the Kaper algorithm) while keeping stabilities and other parameters under control. Some numbers: LOA / LWL (length overall / waterline): 5.500 / 4.945 m, BOA / BWL (beam overall / waterline): 0.452 / 0.420 m. I reduced the boat width to exactly my hip plus 4 fingers (that is: 36 + 9 cm, my fingers are quite big, 9 cm for 4 fingers).

inalized my new kayak design, a considerable amount of work on optimizing the hull shape, adjusting it back and forth to find out the minimum drag numbers (based on the Kaper algorithm) while keeping stabilities and other parameters under control. Some numbers: LOA / LWL (length overall / waterline): 5.500 / 4.945 m, BOA / BWL (beam overall / waterline): 0.452 / 0.420 m. I reduced the boat width to exactly my hip plus 4 fingers (that is: 36 + 9 cm, my fingers are quite big, 9 cm for 4 fingers).