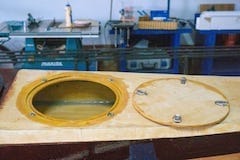

Finishing works on the mast base. Although sail is something not included in this “version” (intended to be installed sometime next year), the mast base need to be ready for now, before the deck and hull are joined together, or else it would be very difficult to work on later. It takes me lots of time shopping around to find the appropriate hardwares to be used as the mast base, and I found some good ones, all made of stainless steel (shown in the 3rd image below).

There’s absolutely no kayak accessories store of any kind in Vietnam whatsoever, so by “kayak hardwares”, I mean I was seeking for something that can be equivalently used on a kayak. Also, it’s very hard to find the parts, cause there’s no common “terminologies” used to name them. When I want to find something, I usually go to the vendors with a picture of the thing I want to have, and they would come out with something similar, that’s how the communications go on!

For the mast base, I glued a small wooden plate under the deck, right at the base position. The base is then bolted down through deck onto this plate, which in turn, glued to a supporting cross – shape structure linking deck with hull. That would be strong enough to withstand the mast and its sail. The mast would be stepped, and rotatable on the base, with four stays to hold it upright. Well, sail when you can, paddle when you must

sounds to be very pleasing on my future journeys.

I covered the hull and deck’s internal sides with a thin layer of white paint. With bright white color, it’s easier to find things in the storage compartments. Then I slightly sanded and painted the bottom with two layer of transparent paint mixed with the puce pigment. A few more miscellaneous jobs needed before the two halves could be joined together. The 5th image below: test fitting the hull and deck, check fitness and some small adjustments here and there.