Someone eventually turns on the tap, and the rainy season is officially here, it comes so late this year. I haven’t had the best physical preparation, been quite busy for the last couple of weeks, but can’t wait anymore to start the long – planned trip. Saying to myself: just do it, go out there, play it “safe and sane”, for whatever the nature might throw at you. I started my trip to Đồng Hoà, the small town – let opposite of Vũng Tàu on the other side of Gành Rái bay, 4:30 AM, June 16th.

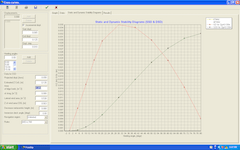

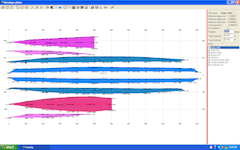

The lunar phase is Waxing Crescent (unlike last year, it was Full Moon), tidal coefficient is in [80 ~ 90] range, a high value (not extremely high), but I don’t really care about them anymore. The general plan is going through Lòng Tàu river to Gành Rái bay (40 km) then 20 km on sea to reach Đồng Hoà. The next day would cross Đồng Tranh bay, then make it through Soài Rạp river back to Sài Gòn (55 km). The area is a complex joinery of many rivers, in essence, going around the Cần Giờ mangrove biosphere reserve.

DAY 1

Leg 1

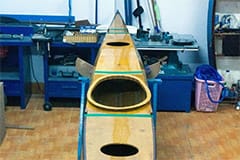

The trip starts smoothly as I expected, speed increases gradually as the tide was coming to help: 6.5, 7.0… 9, 9.5… 11, 11.5, 12… top at 13 kmph, that’s really good. The tide is not as strong as last year, but my HW – 3 kayak goes faster. The Lòng Tàu river is narrow and deep, fast running water with some large, dangerous – looking whirlpools, but that’s all. I finish the first 20 km one hour sooner compared to last trip, which is quite obvious since I paddle now a better kayak, not a 14 footer anymore.

The next leg completed at 9:30 AM, that’s superb! I stop at the river mouth, having a break and lunch for 1 hour, before continue on. The hydrofoils run this route every 45 minutes or so. It’s so fun (and thrilling) to watch it coming straight on you, looking from the head, those “legs” lifting the whole body above the water, exactly like a giant spider. Dangerous spiders indeed, have been causing numerous accidents, fortunately, those Soviet – made machines can be heard many kilometers away.

Leg 2

The next 10 kilometers goes on as smooth, it’s very pleasing to roam the immense, peaceful water space of the estuary. I was thinking I could finish the day within 10 hours of paddling, but life turned out to be not that easy. As soon as I round the Cần Thạnh horn, wind and wave gradually pick up, they get stronger and stronger, and they came straight from where I was going to. I knew that the weather wouldn’t be good these days, but I just didn’t think my next couple of hours to be that hard.

Waves soon reach 4 feet high, and even more, luckily, the wave lengths are still a bit long, they are not too steep. A perfectly – fun environment to play against the waves and winds, as I could rarely be in the same situation again, to horn my “acrobatic skills” with a kayak. I was quite tired already, but still eager to take the chance to enroll in that “advanced kayaking course”. The sky was divided into two halves, one white and and black, from Đồng Hoà direction, a tropical gale was coming.

Leg 3

The last 3 kilometers, I was in the gale, the wind gusts were so terrible that I couldn’t even hold the paddle upright, making advance was really really hard. But I had nothing to fear: I’m quite closed to my target already, the lowering tide seems to make the distance looks further, but actually the water is shallow, less than 2 meters, I could easily beach the kayak at any moment if something goes wrong. I reached Phương Nam Pearl resort at 4:30 PM after 12 hours of paddling, exhausted!

It took 7 hours to complete the first 50, and it took 5 hours to complete the last 10 kilometers! I spent some last daylight hours to wander the beach, the lowered tide left millions of small fishes imprisoned in those water ponds, jumping and sparkling like silver. And the sea birds were gathering for their ‘clamorous’ party, in the mist of heavy rain and strong wind. The resort offered me a 70% discount since it was not weekend, and I need some comforts to recover in preparation for my next day!

Day 2

Leg 4

I begin the next morning slowly with breakfast and coffee, thinking that I could finish the 55km return trip in about 12 hours. It turned out that I’m completely and severely wrong. Departed at 8:30 AM, 10 km across Đồng Tranh bay into the Soài Rạp river mouth, there were some waves, but nothing particularly difficult. I’d thought that it should be calmer on the river, but Soài Rạp is completely different (compared to Lòng Tàu river), it’s just so wide, and the weather deteriorates toward the afternoon.

The next 20 km up the river, I found myself playing the “acrobatic game” again! Waves were large, even larger than yesterday, surely wouldn’t give you a safe feeling at all. And the winds signal that another gale could come at any moment. When it did come at 1 PM, I made a quick decision to immediately take shelter in the mangrove forest, white breaking – waves were all across the river, and I can’t risk wasting my strength since I still have 30 kilometers ahead of me to complete.

Leg 5

It was where the Vàm Cỏ branch joining the Soài Rạp river, turbulences, and the gale was so brutal, I had to wait 1.5 hours before being able to go on. 6 PM, passed Vàm Sát branch, paused for dinner (sliced bread with canned tuna, some bananas). 7 PM, passed Hiệp Phước ferry, it was dark already, and it’s not immediately obvious for me to recognize that my speed stalled significantly. A quick check on the Garmin shows that, even though I was paddling hard, my real speed was under 1.5 kmph.

That means there’s a 5.5+ current here! I’ve never seen such a powerful opposite current! The Garmin map shows a very sharp S – shape river turning, which explains the strong current, and the tide was at its extreme too! I felt very… despondent, only 15 kilometers from my destination, but that would mean many more hours of paddling. I had to continue on anyhow, some desperate paddling struggles, my shoulder was in great pain, and my arms swell up like two bunches of bananas.

Leg 6

The last several kilometers were very painful, I have to stop for a break often, very inconvenient to navigate in the dark along the Hiệp Phước port area, where there’re many freighters traffic. I reached home haft past midnight, after 16 hours of paddling, not exhaustion, but a ‘worn – out’ condition to be correct. But never have I had the idea of giving up, on the other hand, I was feeling very very pleased as I’d completed what’s settled to be done at the beginning of the journey.

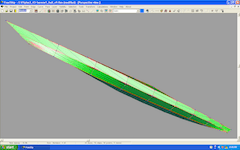

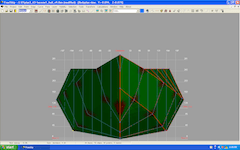

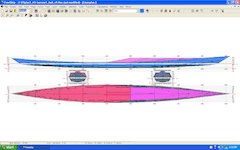

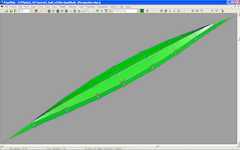

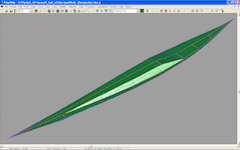

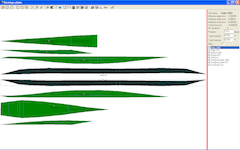

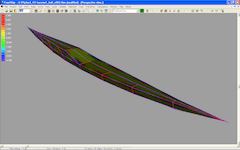

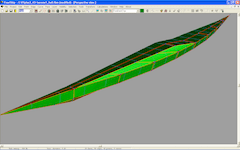

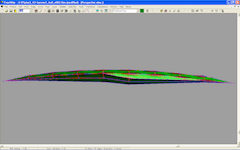

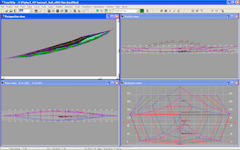

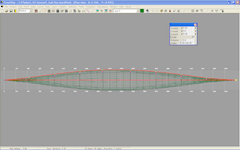

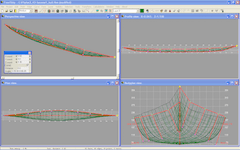

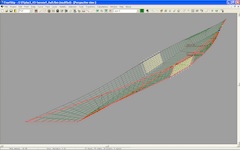

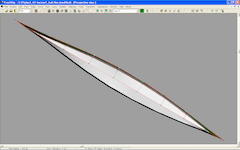

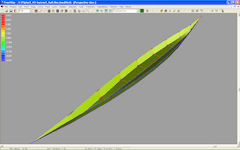

The Garmin – recorded route viewed on Google Earth, first 6 images: the 6 legs of the trip, last 2 images: day 1 & 2 of the trip, the 6th image: the route terminated some kms from my home cause the Garmin battery ran out, I had a pair of backup, but too tired to replace then. Thanks to the Garmin, navigating is easy and convenient. But don’t forget the paper maps, I always check the routes on papers, note down the distances, headings, tide table etc… learn them by heart before any trip.

The rainy season has just come back, at its full throttle these days. It rains cat and dog every afternoon, and there’re gales a few times in a day. Those gales usually won’t last very long, but could be very dangerous since the wind gusts could momentarily reach 7, 8 or more on the Beaufort scale. Just three days ago, a large fishing boat capsized with 37 people on board, right on this Soài Rạp river during a gale, resulting in 2 deaths. So, I proceed my trip with lots of cautiousness.

But after a gale, it’s always very calm, the water looks tranquil as if nothing has happened. And so is my mood, a kind of internal serenity for my mind that I surely wouldn’t trade anything for it. Now sitting here writing these lines, but all I would like to say is that: there’s no wifi on water whatsoever, but I’m sure you would find a better connection there!

, not just a disconnection to the madnesses of modern society, but a true connection to the nature, to your inner self…

You may have noticed from the pictures that I had a life vest on the back of my kayak, but in the gale at the end of the first day, it was blown away, and I continue the rest of the trip without a PFD (Personal Floating Device). During the gale, it is very hard to make a steady picture shot, and something went wrong with my GoPro (it shoots still images instead of videos), and I couldn’t have just a second to fix it, was worrying about a potential capsize, so I missed many of the interesting moments.

The GoPro 3 has some drawbacks, it couldn’t produce fine image quality in lower – lighting conditions, such in a gale, and when water dust has covered all over its glass box, the resulted video is very blurry and obscured. But I don’t really mind, those fascinating moments were in my memory already, like having a higher adrenaline level in your blood, those playful hours facing the big waves, trying to keep your boat balanced, and make advances, meter after meter, to your destination.

This is only my first longer trip, 2 days of hard paddling, 12 hours for the first day, and 16 hours for the second, 115 kilometers in total. Nothing comparable to the feeling, you and yourself, the long road ahead, and a commitement to complete it no matter what. This is the first time I tasted the real hardship that nature could throw at me, gales and waves, strong current… unlike my last year’s trip to Vũng Tàu, in which I was just lucky to have it done smoothly within 12 hours with good weather.

There’re lots of things learned from this trip: some improvements to be made in kayak building, some more adjustments for equipments, gears, preparation for food and drink… the experiences and skills to handle rough conditions… and above all, the understanding you achieve, not only on wind, wave, current, navigation… but on yourself. That’s all about the purposes of longer journeys, you don’t win the mileage, you don’t win the nature (gales or current), you just try to… win yourself!

Đồng Hoà and its nearby sister town Cần Thạnh are both very small but peaceful towns, unlike the much bigger Vũng Tàu city on the other side of they bay. Small communities living on fishing and planting (mango), and tourism. I usually go there on motorbike, for one single day, every few months or so, just to stand by the shores and watching, listening to the sea. Out there, the great blue sphere of ocean, white breaking waves, my “playground” for many years to come!

It’s simply just pleasing to wander the shores when the tide was lowering, or to watch the sun rising with a cup of coffee. You could also go to its fishing harbour to buy some sea foods, or visit the “commune house”, a small local “museum”, which preserves a large whale’s skeleton, and exhibits some models of fishing sail boats that were used by the local inhabitants (images below). Pieces of tradition and history could still be found here and there along this narrow but lovely strip of land.