a nói ngày xưa Hán-tự, chữ nghĩa khó khăn, điều kiện học không có, không giỏi thì cũng chả phải chuyện lạ! Nhưng ngày nay, tiếng Anh dễ hơn nhiều, tư liệu học tập vô tận, mà rồi cũng y như thế! Nên chỉ có thể trách bản thân hời hợt, không có “công phu” gì thôi! Đọc văn bản tiếng Việt nào mà giọng văn kiểu ngọng líu ngọng lo là em không đọc tiếp! Nó nhiều nhan nhản, đến mức lâu lắm rồi em không buồn nói, mấy hôm phải buổi nóng trời, ngứa mồm, đưa một vài ví dụ. Chú thích cho mấy cái ảnh dưới:

a nói ngày xưa Hán-tự, chữ nghĩa khó khăn, điều kiện học không có, không giỏi thì cũng chả phải chuyện lạ! Nhưng ngày nay, tiếng Anh dễ hơn nhiều, tư liệu học tập vô tận, mà rồi cũng y như thế! Nên chỉ có thể trách bản thân hời hợt, không có “công phu” gì thôi! Đọc văn bản tiếng Việt nào mà giọng văn kiểu ngọng líu ngọng lo là em không đọc tiếp! Nó nhiều nhan nhản, đến mức lâu lắm rồi em không buồn nói, mấy hôm phải buổi nóng trời, ngứa mồm, đưa một vài ví dụ. Chú thích cho mấy cái ảnh dưới:

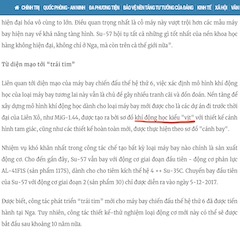

1. Fighter, vừa có nghĩa là chiến binh, vừa có nghĩa là phi cơ tiêm kích, cái này chắc là do người dịch, chứ dịch tự động như Google translate chắc chắn thông minh hơn.

2. Rocket-propelled grenade, dấu ‘-‘ rất quan trọng, là “lựu đạn phóng bởi tên lửa”, chứ không phải “lựu đạn phóng tên lửa”, đảo ngược chủ thể! Nôm na chính là B40, B41, etc…

3. “Khí động học kiểu vịt”: cái này thì phải có công phu “đoán mò” rất siêu mới lần ra được, dịch từ cụm từ “aerodynamic canard-wing”. Chữ “canard” nguyên gốc từ tiếng Pháp, nghĩa là con “vịt thịt” (vịt làm thức ăn, nghĩa phái sinh chính là: “tin vịt, tin ba láp”), nghĩa trong ngành hàng không là cánh phụ, nhỏ của vật thể bay! Vì không hiểu nên người dịch đã phát minh ra một ngành học hoàn toàn mới: Khí động học kiểu vịt! Haiza, báo với chả chí, đúng nghĩa là vịt! Rồi lại như Aziz Nesin: tại cái xứ sở nhiều ruồi quá! 😅

ọc thấy cái này lâu rồi, giờ post lại vẫn thấy buồn cười, trông người mà ngẫm đến ta, cũng chả khác nhau mấy! Ông lão đánh cá trên sông Dniepr kéo lưới được một con cá vàng! Cá xin tha mạng bằng một điều ước!

ọc thấy cái này lâu rồi, giờ post lại vẫn thấy buồn cười, trông người mà ngẫm đến ta, cũng chả khác nhau mấy! Ông lão đánh cá trên sông Dniepr kéo lưới được một con cá vàng! Cá xin tha mạng bằng một điều ước!

ới hơn 2 tháng tuổi nhưng đã nặng gần 2kg… chỉ biết ăn, ngủ và phá… Tuổi đang lớn nên cái đầu thì bé tí, chân tay thì dài lòng khòng, tỷ lệ cơ thể không cân đối và đặc biệt vụng về, chạy đâu vấp đó, va chân, cộp đầu mãi… Có đầy đủ đặc điểm của một đứa trẻ đang lớn:

ới hơn 2 tháng tuổi nhưng đã nặng gần 2kg… chỉ biết ăn, ngủ và phá… Tuổi đang lớn nên cái đầu thì bé tí, chân tay thì dài lòng khòng, tỷ lệ cơ thể không cân đối và đặc biệt vụng về, chạy đâu vấp đó, va chân, cộp đầu mãi… Có đầy đủ đặc điểm của một đứa trẻ đang lớn:

a nói ngày xưa Hán-tự, chữ nghĩa khó khăn, điều kiện học không có, không giỏi thì cũng chả phải chuyện lạ! Nhưng ngày nay, tiếng Anh dễ hơn nhiều, tư liệu học tập vô tận, mà rồi cũng y như thế! Nên chỉ có thể trách bản thân hời hợt, không có “công phu” gì thôi! Đọc văn bản tiếng Việt nào mà giọng văn kiểu ngọng líu ngọng lo là em không đọc tiếp! Nó nhiều nhan nhản, đến mức lâu lắm rồi em không buồn nói, mấy hôm phải buổi nóng trời, ngứa mồm, đưa một vài ví dụ. Chú thích cho mấy cái ảnh dưới:

a nói ngày xưa Hán-tự, chữ nghĩa khó khăn, điều kiện học không có, không giỏi thì cũng chả phải chuyện lạ! Nhưng ngày nay, tiếng Anh dễ hơn nhiều, tư liệu học tập vô tận, mà rồi cũng y như thế! Nên chỉ có thể trách bản thân hời hợt, không có “công phu” gì thôi! Đọc văn bản tiếng Việt nào mà giọng văn kiểu ngọng líu ngọng lo là em không đọc tiếp! Nó nhiều nhan nhản, đến mức lâu lắm rồi em không buồn nói, mấy hôm phải buổi nóng trời, ngứa mồm, đưa một vài ví dụ. Chú thích cho mấy cái ảnh dưới:

avel Belov, vị tướng Nga rất nổi tiếng trong WW2, nói theo ngôn ngữ ngày nay là liên tục lên bảng tin chiến sự nóng hàng ngày của Phát-xít Đức, tư lệnh một quân đoàn kỵ binh Nga… Vâng, chính là hành quân và đánh nhau bằng ngựa, giữa một thời đại đã cơ giới hoá cao độ, xe tăng, máy bay không thiếu thứ gì, mà vị tướng Nga người Đức ngưỡng mộ nhất lại là kỵ binh!

avel Belov, vị tướng Nga rất nổi tiếng trong WW2, nói theo ngôn ngữ ngày nay là liên tục lên bảng tin chiến sự nóng hàng ngày của Phát-xít Đức, tư lệnh một quân đoàn kỵ binh Nga… Vâng, chính là hành quân và đánh nhau bằng ngựa, giữa một thời đại đã cơ giới hoá cao độ, xe tăng, máy bay không thiếu thứ gì, mà vị tướng Nga người Đức ngưỡng mộ nhất lại là kỵ binh!

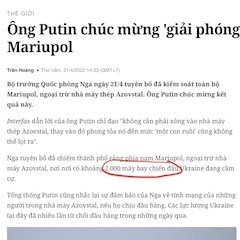

au khi Sa-hoàng Peter-3 chết, có người mạo danh, lan truyền tin đồn rằng mình chính là Peter-3 còn sống, đó là Yemelyan Pugachev, người nổi dậy chống chính quyền nữ hoàng Catherine-2. Sau khi Sa hoàng Alexander-1 chết cũng vậy, có tin đồn rằng ông ta thực ra chưa chết, mà chỉ đi tu dưới cái tên mới Feodor Kuzmich. Suốt thời phong kiến, gần như lúc nào cũng có tin đồn như thế, để người ta nghi ngờ tính “chính danh” của người cầm quyền!

au khi Sa-hoàng Peter-3 chết, có người mạo danh, lan truyền tin đồn rằng mình chính là Peter-3 còn sống, đó là Yemelyan Pugachev, người nổi dậy chống chính quyền nữ hoàng Catherine-2. Sau khi Sa hoàng Alexander-1 chết cũng vậy, có tin đồn rằng ông ta thực ra chưa chết, mà chỉ đi tu dưới cái tên mới Feodor Kuzmich. Suốt thời phong kiến, gần như lúc nào cũng có tin đồn như thế, để người ta nghi ngờ tính “chính danh” của người cầm quyền!

hương trình phim ảnh cuối tuần… 🙂 Tháng 6, 1941, nước Đức Phát-xít tiến hành chiến dịch Barbarossa đưa quân vào lãnh thổ Xô-Viết, quân đội LX thiếu chuẩn bị, nhanh chóng gặp nhiều thất bại và buộc phải rút lui, lần lượt phải bỏ cả Kiev, bỏ Kharkov (Ukraine bây giờ)… một trại giam được lệnh sơ tán về tuyến sau.

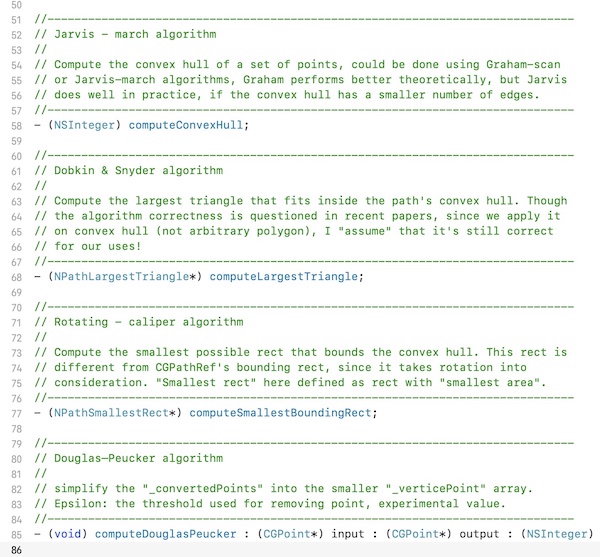

hương trình phim ảnh cuối tuần… 🙂 Tháng 6, 1941, nước Đức Phát-xít tiến hành chiến dịch Barbarossa đưa quân vào lãnh thổ Xô-Viết, quân đội LX thiếu chuẩn bị, nhanh chóng gặp nhiều thất bại và buộc phải rút lui, lần lượt phải bỏ cả Kiev, bỏ Kharkov (Ukraine bây giờ)… một trại giam được lệnh sơ tán về tuyến sau. ối tiếp post trước, minh hoạ bằng một screenshot – chụp màn hình. Đến tận bây giờ vẫn còn xài khá nhiều toán, không phải là Toán cao cấp (vi phân, tích phân, đạo hàm, xác suất thống kê, etc…) mà chủ yếu là Toán rời rạc (discrete mathematics) và Thuật toán, thuật giải, thêm một chút Hình và Số… Chính là vì mấy cái này nên code vẫn còn có vài niềm vui, ngoài những chuyện debug phức tạp, nhức đầu, mệt mỏi và vô số những công việc… trâu bò khác!

ối tiếp post trước, minh hoạ bằng một screenshot – chụp màn hình. Đến tận bây giờ vẫn còn xài khá nhiều toán, không phải là Toán cao cấp (vi phân, tích phân, đạo hàm, xác suất thống kê, etc…) mà chủ yếu là Toán rời rạc (discrete mathematics) và Thuật toán, thuật giải, thêm một chút Hình và Số… Chính là vì mấy cái này nên code vẫn còn có vài niềm vui, ngoài những chuyện debug phức tạp, nhức đầu, mệt mỏi và vô số những công việc… trâu bò khác!

ài hay, ít nhất cũng nên nói cho đám ngu biết nó ngu chỗ nào, qua đó cũng cho thấy sự thảm hại, vô phương của giáo dục VN hiện tại! Nhớ hồi hơn 20 năm trước, lúc nào đạp xe đi học về cũng ghé quầy sách ngoại văn của Fahasa góc gần Sở thú Sài Gòn, tìm mua mấy cuốn Vi tích phân, sách tiếng Anh, bán sale đồng giá! Kiến thức thì cũng tương tự Toán cao cấp như ở Việt Nam thôi! Nhưng khác ở chỗ: sách có hàng ngàn ví dụ về cách áp dụng thực tế, rất sinh động, trực quan, kèm theo rất nhiều hình vẽ, ảnh minh hoạ đẹp!

ài hay, ít nhất cũng nên nói cho đám ngu biết nó ngu chỗ nào, qua đó cũng cho thấy sự thảm hại, vô phương của giáo dục VN hiện tại! Nhớ hồi hơn 20 năm trước, lúc nào đạp xe đi học về cũng ghé quầy sách ngoại văn của Fahasa góc gần Sở thú Sài Gòn, tìm mua mấy cuốn Vi tích phân, sách tiếng Anh, bán sale đồng giá! Kiến thức thì cũng tương tự Toán cao cấp như ở Việt Nam thôi! Nhưng khác ở chỗ: sách có hàng ngàn ví dụ về cách áp dụng thực tế, rất sinh động, trực quan, kèm theo rất nhiều hình vẽ, ảnh minh hoạ đẹp!